The Promise of Waterjet Technology for Micromachining

The potential benefits of using waterjet technology to produce parts or part features smaller than 300 microns are compelling. Developers and researchers are getting close to breaking the barriers that stand in the way of micromachining in the 150- to 200-micron range and below.

Share

Creating a high-pressure stream of water bearing an abrasive grit has proven to be a very effective way of cutting metal, plastic, glass and many other materials. Waterjet machining is the common name for this process. With multi-axis stream control and other accessories in place, it is possible to cut 3D forms to a level of precision and accuracy that matches or exceeds other metal removal processes. However, in many cases, waterjet machining has additional benefits.

It may cut faster. It leaves no heat-affected zone. Workpiece materials do not need to be electrically conductive or non-reflective. Change-over time can be minimal because only the new part program has to be downloaded to the CNC.

Highly flexible and capable, waterjet continues to find new applications in precision manufacturing, especially in cases where cost-effectiveness and fast turnaround are critical. One area that has attracted considerable attention is applying waterjet to the production of parts in the “micro” range, that is, parts or part features smaller than 300 microns. R&D efforts are currently focused on making waterjet practical in the 150- to 200-micron range.

Dr. Peter Liu, senior scientist at Omax Corporation (Kent, Washington) is deeply involved in exploring the frontier of micro-abrasive waterjet technology, as it is called. In fact, his on-going efforts to further the development of this process are supported by a grant from the National Science Foundation Small Business Innovation Research Program (NSF SBIR Phase II grant 1058278) as well as Omax’s own R&D funds.

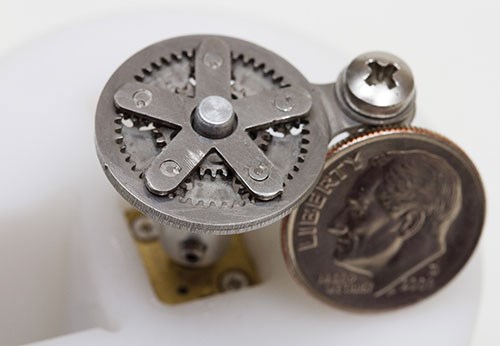

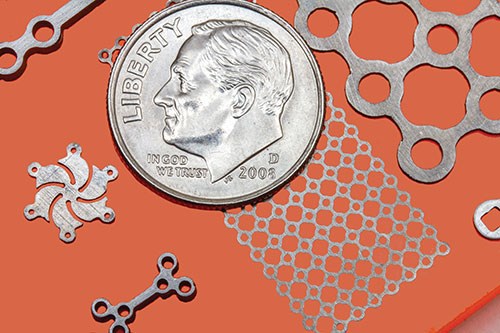

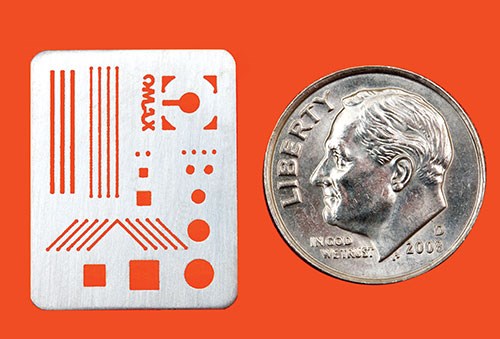

As the gallery of sample parts shown in this article demonstrates, waterjet is already capable of remarkable success in producing small parts and features. To push waterjet technology to greater capability in the micromachining arena, Dr. Liu says that research efforts must overcome barriers in three critical areas.

One is a practical method to produce a nozzle orifice 100 microns or smaller in diameter. Current methods cannot produce a hole this small with adequate roundness or straightness, he says. Wear resistance of the nozzle material is also a problem.

Likewise, a mixing tube, the component of the stream delivery system in which water and the abrasive particles meet to form a slurry, must be designed to function effectively on a highly miniaturized scale. Downsizing current designs is limited by the existing science in fluid dynamics. For example, researchers are studying surface tension, capillary action, supersonics and the Venturi effect for insights that may lead to breakthroughs.

For waterjet micromachining, the size of abrasive particles must be reduced proportionately. Thus, a third challenge is developing methods to feed abrasive particles in orders of magnitude finer than is currently feasible. Because the behavior of ultra-fine particles is not fully understood (particularly in the area of gravity feeding), achieving constant flow rates for consistent and predictable cutting quality has been elusive.

Despite these challenges, Dr. Liu feels he has made considerable progress in the development of micro-waterjet machining technology. He expects this technology to become a viable process with competitive advantages for micro-machining applications in the targeted micro-range. He predicts a two- to four-year time frame for this achievement.

In the meantime, manufacturers must look closely at waterjet and think creatively

about opportunities it presents for making extremely small parts to high precision.

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreRead Next

Picking the Right End Mill

Kennametal global product manager Katie Myers explains how cutting tool features can impact machining strategies for different materials.

Read MoreWhy We Ask Machine Shop Leaders to Speak at TASC – The Automated Shop Conference

TASC is our industry’s premier peer-to-peer automation stage where America’s shop leaders refine the art of metalworking and CNC machining. For conference speakers, it's also an opportunity to showcase your skills and gain exposure for your business. Here are five why stepping into the spotlight at TASC could be your smartest move toward elevating your shop.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More