Why Not Start With Waterjet?

In titanium, significant savings and process efficiency can result from the simple fact that abrasive waterjet cutting leaves the remaining stock intact.

Share

Titanium is an expensive metal, and it’s difficult to machine. Or is it?

While many would agree with the first part of that sentence, David Kvasnicka says the second part isn’t necessarily true. He is a Chicago-area regional manager for abrasive waterjet machine tool maker Omax, serving manufacturers who are machining titanium for various markets—making small medical components or large aerospace structures, among other parts. In the context of abrasive waterjet, he says titanium is not a difficult metal. It is seen as a soft material that is relatively easy to cut.

That fact has implications for almost any manufacturer that machines titanium components on a CNC machining center. In this metal, the most efficient machining process might not be one in which one machining center alone does all the work—as streamlined and simple as that processing strategy might seem. Instead, for parts of the right thickness, abrasive waterjet can be more efficient than milling at cutting away the rough stock. It can be so much more efficient than milling that it often makes sense to add waterjet machining to the process, allowing waterjet to cut the part to near net shape before delivering the part to the machining center solely for the finishing operations.

The benefits go beyond productivity, Mr. Kvasnicka says. A secondary benefit relates to scrap value. The solid skeleton of material left behind after waterjet is significantly more valuable than the same material reduced to the form of chips. Again, titanium is expensive, making it all the more important to recapture more of that expense by keeping the material intact.

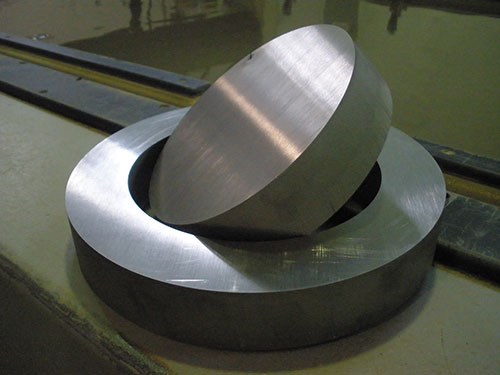

Thick Stock

Though abrasive waterjet cutting is frequently associated with sheet metal, Mr. Kvasnicka says routine applications cut billet stock up to 4 inches thick. Non-routine applications succeed at cutting stock around 12 inches thick.

In titanium, waterjet does what laser cutting cannot. Because of titanium’s heat absorption, cutting it with a laser leaves a heat-affected zone. By contrast, waterjet is a cold-cutting process that does not structurally modify the material.

Precision also is tighter than what many who have not been exposed to modern waterjet cutting technology would expect, he says. Thanks in large part to control features that compensate for kerf and other known waterjet error sources, it is now common to hold accuracies of 0.001 inch in waterjet machining. The surface finish does not match what some other machining methods can achieve, but in the case of non-critical aircraft parts that need only precision and not finish, parts are often delivered into assembly directly after the waterjet cutting.

Two for One

The fact that waterjet does not reduce the stock to chips might be the most meaningful advantage of this type of cutting. In expensive metals, that advantage can have a significant impact even if the leftover stock is never sold for scrap. Nesting is the reason, Mr. Kvasnicka says. Adjacent pieces in waterjet cutting can nest together with only 1/16 inch of stock between them. Makers of titanium structural members for aircraft are often accustomed to seeing more than half of the material removed from the workpiece as chips. How might the process change if that stock could remain solid?

He says nesting has led to dramatic productivity improvements in some applications. In the case of one aerospace manufacturer, replacing rough milling with waterjet let the shop nest two pieces into a block of titanium that used to deliver only one piece. Thus, thanks to the freedom to nest parts very close, it might be possible to turn previously leftover material not into quality scrap, but into something even better: quality parts.

Related Content

Shop Tour Video: From Garage Shop to Leading Aerospace Supplier

From repairing aircraft interiors to manufacturing medical implants, Superior Joining Technologies excels at CNC machining, TIG welding, laser welding, and NADCAP-accredited nondestructive testing. Discover how this Rockford-based company supports the aerospace industry through a combination of advanced technologies.

Read MoreSolar Atmospheres Receives Northrop Grumman Approval for South Carolina Facility

All five Solar Atmospheres facilities are now an option for customers with Northrop Grumman requirements for vacuum heat treating.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreThe Role of Surface Finishing in Modern Manufacturing: Trends and Best Practices

You’re attending IMTS to advance your business. Regardless of your role in the manufacturing process, considering how your parts will be finished is crucial. This article can help you understand trends in surface finishing and better communicate with your finishing partners.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreWhy We Ask Machine Shop Leaders to Speak at TASC – The Automated Shop Conference

TASC is our industry’s premier peer-to-peer automation stage where America’s shop leaders refine the art of metalworking and CNC machining. For conference speakers, it's also an opportunity to showcase your skills and gain exposure for your business. Here are five why stepping into the spotlight at TASC could be your smartest move toward elevating your shop.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More