Tooling

Latest Tooling News And Updates

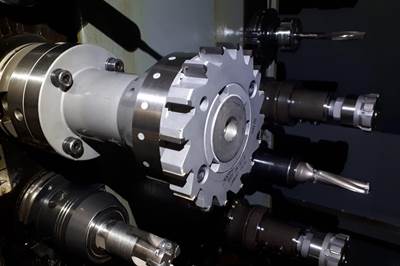

Tungaloy Milling Tool Provides Enhanced Edge Strength

The MillQuadFeed cutting tool features a specialized insert geometry that is said to reduce cutting resistance by up to 20%, enhancing machining efficiency.

Read MoreForkardt Hardinge Swiss Workholding Provides Reliable, Consistent Performance

The company’s Swiss collets are designed to securely hold parts without marring surfaces, minimizing vibration to ensure smoother machining, enhanced accuracy and extended tool life.

Read MoreInside the Process of Cutting Tool Recycling

Global Tungsten & Powders, part of the Ceratizit Group, sheds light on the processing steps that convert a shop’s used inserts into new tools and other applications.

Read MoreIndexable Drill Heads Double Profitability

Moving to a robust line of indexable drills enabled this shop to dramatically alter the manufacturing process for a problem part, doubling its profitability.

Read MoreSandvik Coromant Toolholding System Provides Rapid Tool Changes

QS Micro features quick and easy tool changes with a high degree of modularity and is well suited for small-part machining operations.

Read MoreSimtek Milling Tool Features Monoblock Performance Features

The SimMill 9W4 tool milling system is designed to work precisely and stably under difficult conditions, such as in limited space with long overhang lengths.

Read MoreFeatured Posts

Measuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.

Read MorePowRgrip Responds to Three Tooling Trends

Rego-Fix’s PowRgrip tooling system has expanded over the past 20 years to incorporate a wider range of tool sizes, as well as automation.

Read MoreAdvanced CAMs Simplify Programming of Conical Barrel Cutters

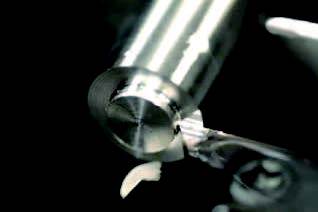

Conical barrel cutters have grown in popularity thanks to the large stepovers that reduce the time needed for some finishing processes, but advanced CAM systems can dramatically improve their usefulness.

Read MorePrioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreRego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read MoreThrough-Coolant System Cuts Nickel-Alloy Cycle Times by 70%

Decker Machine Works recently adopted Rego-Fix’s reCool through-coolant system for ER collets, reducing the cycle times on a nickel alloy job by 70%.

Read More

.jpg;maxWidth=300;quality=90)